FIRESTOP SYSTEMS TESTED TO WITHSTAND MOVEMENT

Our fire protection systems come with a range of approvals according to the latest industry standards

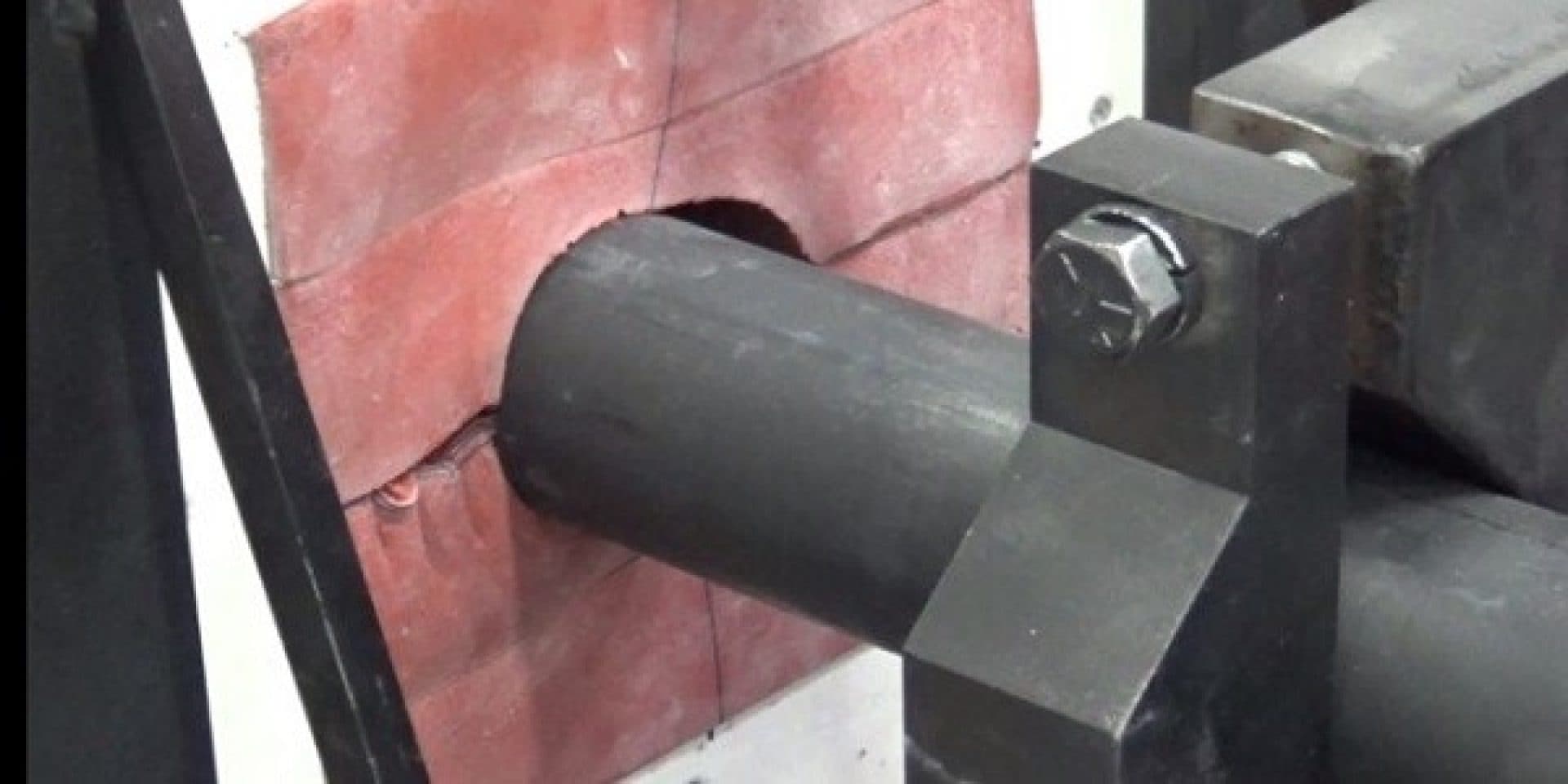

Movement test in perpendicular direction

Movement test in parallel direction