Solutions for electronics projects

From fastening to fire protection – explore solutions designed to reduce contamination in electronic facilities

Process industry and mission-critical facilities have complex infrastructure requirements. For example: electronics projects need to be installed with minimal contamination.

Hilti can support whole project lifecycles with:

- Design engineering and building information modeling (BIM) to get projects off the ground faster

- Prefabrication and advanced logistics to save time and installation costs

- Modular systems for MEP and innovative firestopping, along with advanced solutions for fastening to concrete and steel, for more flexibility

- Specialist software and engineering support to make product selection simpler and fully compliant.

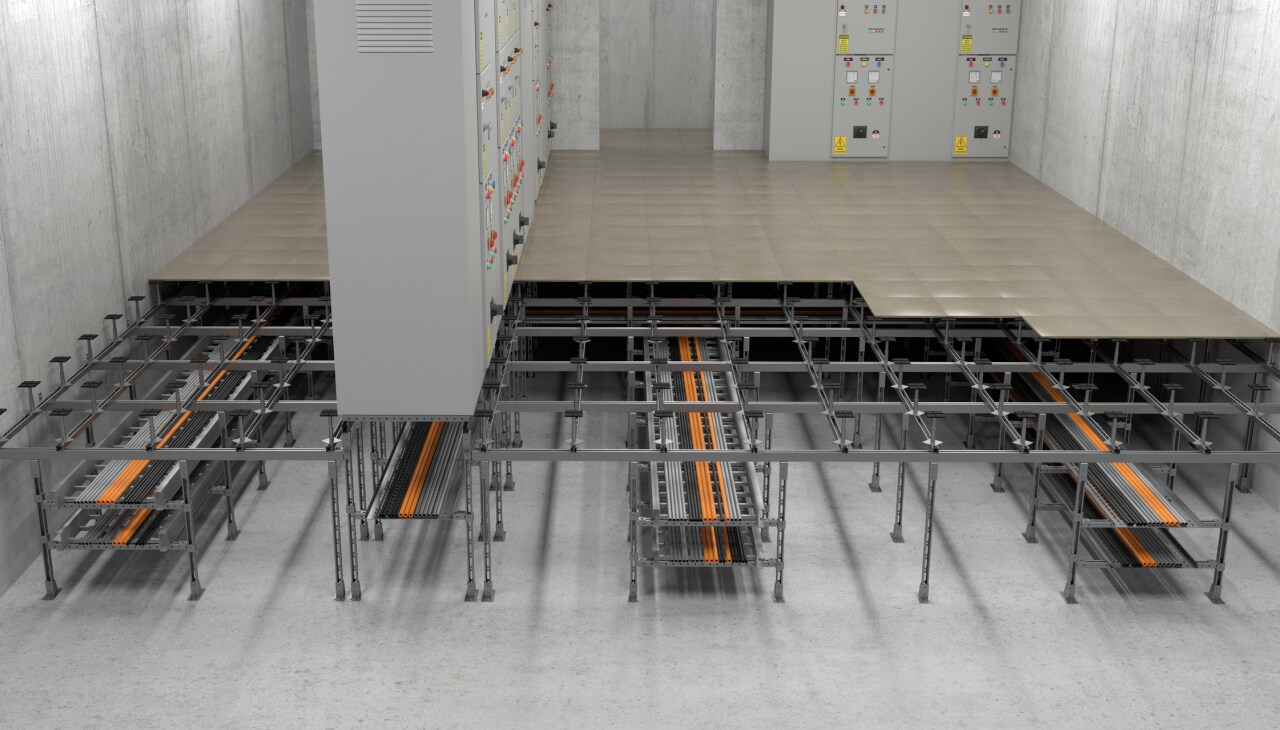

Multidisciplinary support racks

Modular solutions for routing services in clean and non-clean environments in electronics facilities

Electronics facilities depend on a wide range of process and utility piping, complex ductwork, and electric distribution systems. When you make MEP design and installation more efficient, you can reap major cost savings when routing multiple services in fabrication plants and through central utility buildings to water plants. Hilti helps you achieve this with modular multidisciplinary racks and off-rack supports that provide you with a faster, easier-to-install and adjustable solution. From conceptual design to certified engineering analysis and drawings, 3D modeling for BIM to certified 2D shop drawings and BOM, and from off-site pre-assembly to on-site support and training, we can help keep your projects faster, cleaner and more cost-effective.

Fire protection for controlled environments

Fiber-free solutions for pressurized and clean environments in electronics facilities

Traditional firestopping solutions can result in major problems in electronics industry projects. Products such as firestop-coated bats can release fibers into controlled environments in the case of re-penetration. The Hilti portfolio solves this problem by providing a range of fiber-free solutions for different applications. They can be used in conjunction with modular cable transit systems where penetrations are made into pressurized and contamination-controlled areas. They can also provide an effective seal for cable trays, pipes, trays and ducts. Products range from cast-in devices in concrete slabs, through to firestop blocks, bandages and foams. Innovative speed sleeves are ideal for use in applications where cable configurations need to be changed regularly.

Fastening on steel – no welding required

Cordless solutions to minimize contamination when fastening on steel in electronics facilities

The faster, safer and less contaminating it is to fasten on steel, the better it is for electronics industry projects. For example, if you need to fix light supports for condensation pipes, install decking or grating, or add brackets to secondary beams, you need a method that doesn’t rely on labor-intensive welding, contaminating through-bolting or fiddly, high-maintenance multi-piece clamps. Hilti solves this with a suite of direct fastening solutions that comply with relevant standards and approvals. Hilti fasteners can be installed quickly by a single operative using corded, cordless or powder-actuated hand tools. Where no through penetration of paints is allowed, blunt tip fasteners can also help ensure that post-install touch up is not required.

Flexible supports for electronics projects

Use cast-in anchor channels in pre-cast waffle slabs for faster, more cost-effective supports

Quicker-to-install cast-in anchor channels give you a more flexible and adaptable method to incorporate fastening points for a variety of static and dynamic loads. Many electronics facilities install them in pre-cast waffle slabs between clean rooms and clean sub-fabs. This offers significant cost and schedule benefits, ensuring you can anchor substructures such as modular MEP supports more quickly, safely and cleanly. When you need to change configuration, it is simpler to reattach the same supports using new anchors – and without the need for welding or through-penetration. Hilti anchor channels are a high-performance solution, designed for challenging loads and design parameters. They are also approved for static, fatigue, seismic and fire loading.

Equipment fastening without cast-in rebar

Choose flexible post-installed anchoring for tanks, boilers and utility devices in electronics projects

In electronics manufacturing facilities, there is a need to safely anchor a wide range of industrial equipment. This category includes items such as tanks and boilers, as well as utility devices. Hilti simplifies can help simplify equipment installation thanks to a full range of post-installed chemical and mechanical anchors which meet the latest and most rigorous standards and approvals. Anchors can be installed more quickly by single operatives and offer a much more flexible alternative to traditional rebar. PROFIS software makes selecting the correct anchors simpler, while effective diamond drilling tools make it easiery to cut through rebar in concrete where needed. Hilti offers full site support with pull tests, giving you peace of mind that your equipment is installed safely and securely.

Energy and industry project solutions

From mining to onshore oil and gas to shipbuilding, bring down the total costs of your asset over its entire life cycle with end-to-end project solutions that combine software, hardware and services.

Explore end-to-end project solutionsProtect your teams

To help you reduce the risk of accidents and injuries on your jobsites, we invest heavily in safety technologies – whether it's tool-based dust control solutions, training, or systems for tracking worker certication.

Explore safety solutionsControl tool costs

Simplify your financial planning and administration with our fleet management service. Pay a fixed monthly fee for all your tools including their use, service and repair costs. Say goodbye to hidden costs.

Explore Tool Fleet management